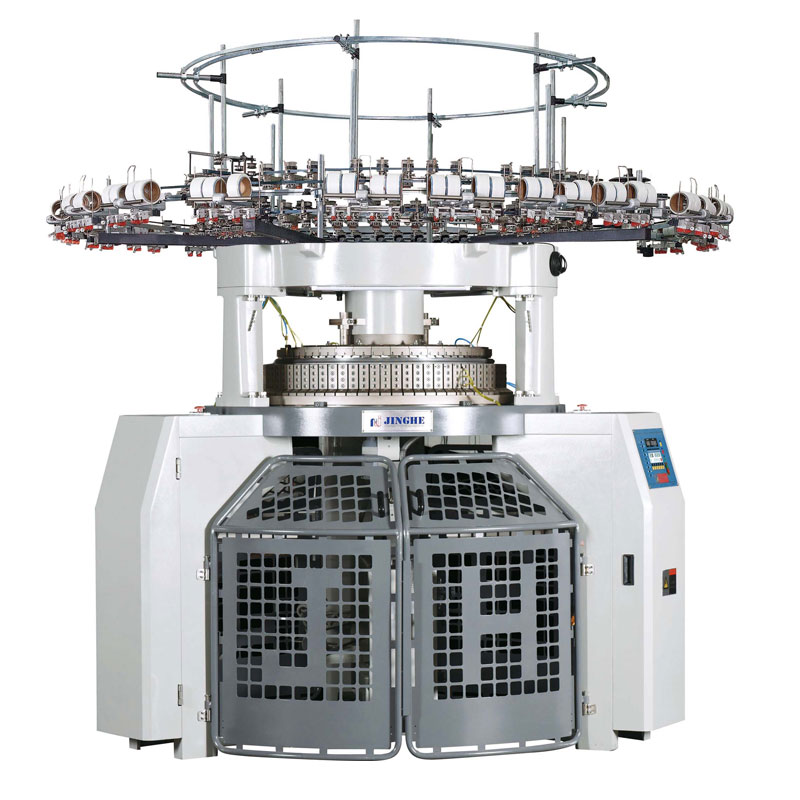

High Feeder Double Jersey Interlock Circular Knitting Machine

- Information

- Video

High Speed Circular Knitting Machine

Product description:

The Double Jersey Interlock Circular Knitting Machine offers several advantages in the knitting process.

Firstly, it allows for the production of fabrics with a double-faced structure, which means that both sides of the fabric have a uniform appearance. This is because the machine has two sets of needles that work simultaneously to create two layers of fabric that are interlocked together.

Secondly, this type of machine is versatile and can produce a wide range of fabrics, including those with different patterns, textures, and weights. It can also be used to knit fabrics with different fiber blends, such as cotton, wool, or synthetic fibers.

Thirdly, the Double Jersey Interlock Circular Knitting Machine is efficient and can produce fabrics at a high speed, which makes it suitable for large-scale production. Additionally, it requires minimal manual labor and can produce fabrics with minimal waste.

Overall, the Double Jersey Interlock Circular Knitting Machine offers several advantages that make it a popular choice for producing high-quality fabrics efficiently and effectively.

The high feeder double-layer knitting ring knitting machine is a professional knitting equipment with efficient production capacity and special feeding structure. This knitting machine adopts a circular belt operation mode, which can achieve the knitting production of double-layer fabrics.

The high feeder double-layer knitting ring knitting machine has the following characteristics and functions:

Efficient production: Adopting a circular belt design to achieve continuous movement of the fabric, fast feeding speed, and improved production efficiency.

Double layer knitting: This machine can simultaneously knit two layers of fabric, making the product more uniform and dense.

Network structure optimization: For double-layer knitting, this model optimizes the loop structure to make the operation of the two layers of fabric more stable and tight, effectively avoiding line crossing and fabric organization misalignment.

Precision Control System: Equipped with advanced control systems, it can adjust the operating speed, needle count, and other parameters of the knitting machine to meet different knitting needs.

Multifunctional needle plates: If necessary, this model can be equipped with different types of needle plates to meet different knitting requirements and expand the variety and application range of knitted products.

Diversified Knitting Products: High feeder double layer knitted loop knitting machine can produce various knitting products, including clothing, household goods, sports equipment, etc.

It should be noted that the high feeder double layer knitting belt knitting machine is a professional equipment suitable for larger production enterprises in the textile industry. For general consumers, understanding and understanding its principles and applications is not common. The purchase and use of this equipment usually require experienced professionals to operate and maintain it.

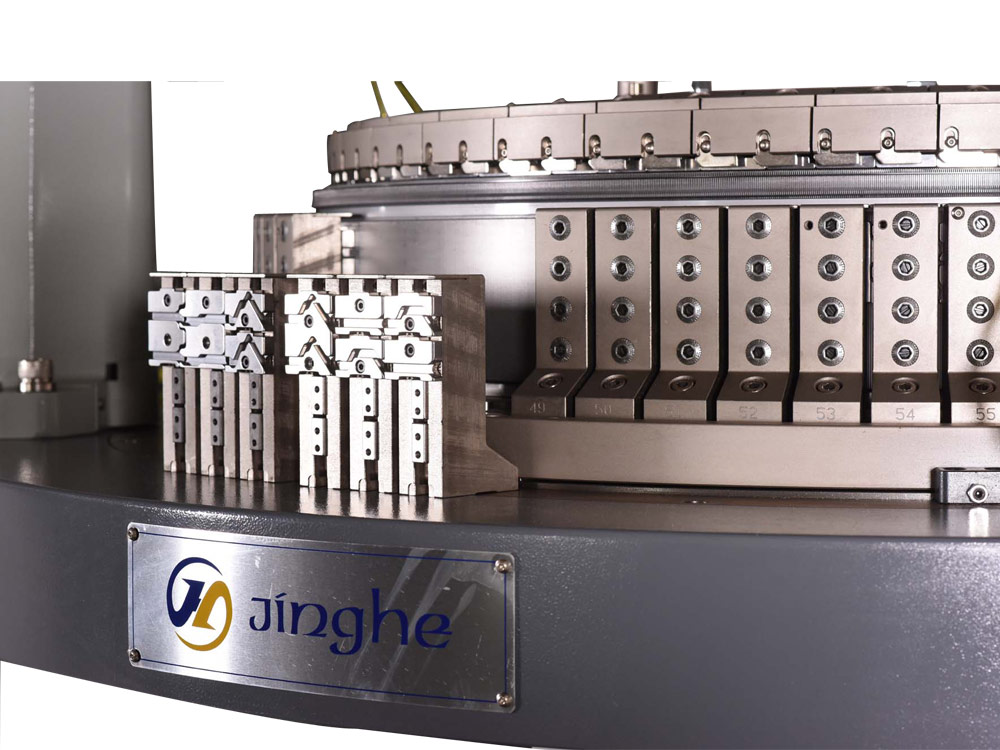

Circualr knitting machine Heart of Circular knitting machine

CNC machinging center Digital controlled lathe

Technical Data

| Diameter | Feeders | Gauge | RPM |

| 25"-38"/2.1 | 52F-84F | 12G-40G | 18-40R.P.M |

| 25"-44"/2.4 | 60F-106F | 12G-40G | 18-40R.P.M |

| 30"-34"/3.2 | 96F-108F | 12G-32G | 18-40R.P.M |

| 25"-44"/2.8 | 70F-122F | 12G-32G | 18-40R.P.M |

Packing&Delivery

Packing:

Wooden box package is our standard & recommended packing, and the machine will be in sealed status. If export to european countries,the wooden material will be fumigated. For remoted countries, we suggest to use vacuum package.

Delivery time:

Basic Machine:30-35days

Jacquard Machine:45-50days

Cusomized Machine: 50days or More(depends on different situations)

Payment: TT or L/C is acceptable

Assembly workshop Cylinder workshop

CNC maching center Shipping goods

Certificate:

Application Area: Vest, T-shirt, Polo shirts, functional sportswear and underwear or seamless clothes(small size).

Applicable Yarn Materials: cotton, synthetic fiber, silk, artifical wool, mesh or elastic cloth.

Contact us:

![]() QuanZhou JingHe YuanWei Knitting Machinery Co.LTd

QuanZhou JingHe YuanWei Knitting Machinery Co.LTd

Add: Inside Honglei Stone Factory,Liaocuoqian,Luoyang Town, Hui'an County, Quanzhou City, Fujian Province, China

Phone/Whatsapp:+8613506078504

Website:https://www.jhknitmachinery.com/

Company Profile:

QuanZhou JingHe Circular Knitting Machinery Co.,LTD is the leading supplier of Circular Knitting machine, mainly produce Single Jersey Circular knitting machine, Double Jersey circular knitting machine,Jacquard Circular knitting machine.

Flexible customization and innovation, Strictly inspect each process of the product in the production process. Quality-oriented is the production philosophy of our factory, we strictly require that every process reach high standard. Therefore , a small screw must be layer of screened to ensure that each one must be bester

Advanced and intelligent production equipment and scientific management mode ensure that every detail from zero to the whole can be tracked in place. We have even established a complete service system for our customers, so that every customer is assured of our products and satisfied with our pre-sales and after-sales.