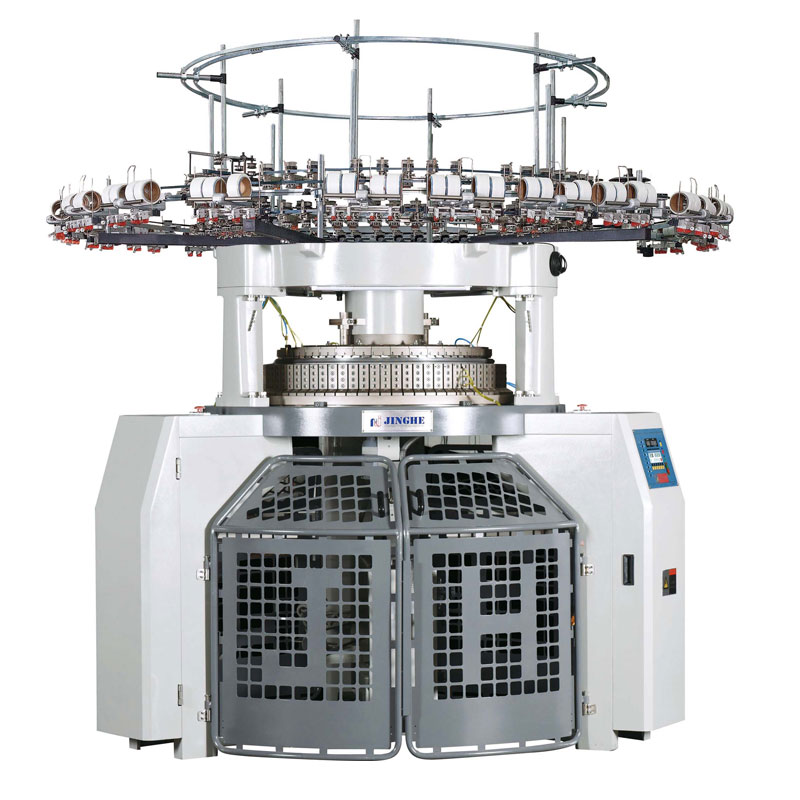

High Quality Interlock Double Jersey Circular Knitting Machine

- Information

- Video

High Speed Circular Knitting Machine

Product description:

● 1.The cylinder seat is to prevent the bottom of the machine from spilling oil on the fabric. Both the large plate and the yarn feeder transmission gear box adopt oil-immersed design, which improves the stability, reduces noise and the influence of the fabric due to braking. The new large plate and large plate gear system can better support the long-term load impact of high tension and high load.

● 2.Powerful air dust fan and rotating nozzle can further enhance the dusting effect. Cam base can reduce batt accumulation. We have solved the problems that may occur under high-speed production for customers in advance。

● 3.The machine with 4 track production ordinary plain fabric and organization fabric, which are used in sports fabrics and casual clothing. Besides . from thick gauges to fine gauges; from small diameters to big diameters; from common fabric to bedding fabric ; from high-volume single yarn weaving to multi-spraying .and that can be equipped with open-width system and high-rolling frame . All of the above can be produced by this model to satisfy the various needs of different customers

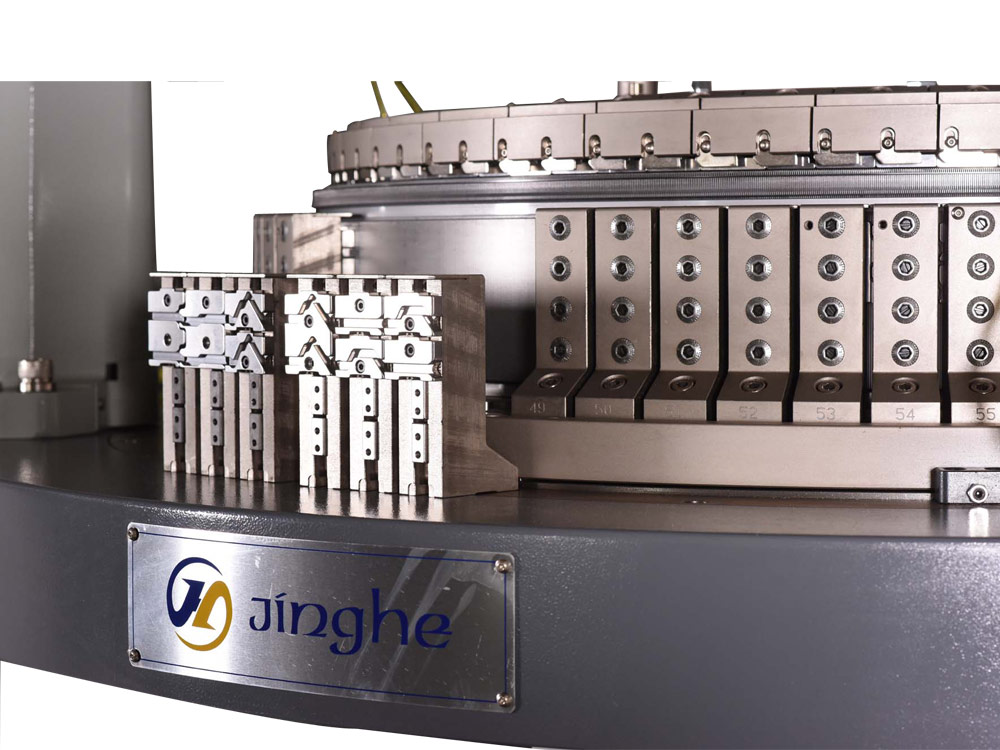

Circualr knitting machine Heart of Circular knitting machine

CNC machinging center Digital controlled lathe

Time flies, and technology is changing rapidly. In the textile industry, a new technology called high-speed circular knitting machine is gradually emerging. It has attracted widespread attention from industry experts and enterprises due to its excellent performance and efficient production speed. So, what exactly is a high-speed circular knitting machine? How will it change the future of the textile industry?

High speed circular knitting machine, as the name suggests, is a knitting equipment constructed based on circular needle plates. Compared to traditional flat needle knitting machines, high-speed circular knitting machines have made qualitative breakthroughs in speed, efficiency, and flexibility. The high-speed circular knitting machines currently appearing in the market are mainly divided into two types: electronic control and computer control. These machines use advanced automation technology to achieve higher production efficiency and more stable working performance.

Compared with traditional knitting machines, high-speed circular knitting machines have obvious advantages. Firstly, due to the use of electronic or computer control technology, it can achieve higher working speeds and greatly shorten the production cycle. Secondly, high-speed circular knitting machines have higher production efficiency and lower energy consumption, effectively improving the profit margin of enterprises. In addition, the equipment also has a more flexible production capacity, which can quickly adjust product styles according to demand and adapt to the changing needs of the market.

In the textile industry, high-speed circular knitting machines have begun to be widely used. It is commonly used to produce various types of clothing, fabrics, and home textiles, whether it is wool, cotton, or chemical fiber materials, which can be efficiently produced through this equipment. Meanwhile, due to the simple operation of high-speed circular knitting machines, the technical requirements for workers are reduced, greatly improving the stability and work efficiency of the production line.

However, the introduction of high-speed circular knitting machines was not smooth sailing. Firstly, due to the high investment cost required for this equipment, there may be some pressure for some small textile enterprises to purchase high-speed circular knitting machines. Secondly, the equipment has high requirements for operational technology and maintenance, and for textile manufacturers without corresponding strength, they may encounter more difficulties during use.

Despite some challenges, high-speed circular knitting machines have still attracted great attention and interest in the textile industry. Many well-known enterprises have begun to actively invest in the research and production of this equipment, and continuously improve its technology and performance. It can be foreseen that high-speed circular knitting machines will become the future trend of the textile industry, bringing more efficient and competitive production methods to the industry.

Technical Data

| Diameter | Feeders | Gauge | RPM |

| 25"-38"/2.1 | 52F-84F | 12G-40G | 18-40R.P.M |

| 25"-44"/2.4 | 60F-106F | 12G-40G | 18-40R.P.M |

| 30"-34"/3.2 | 96F-108F | 12G-32G | 18-40R.P.M |

| 25"-44"/2.8 | 70F-122F | 12G-32G | 18-40R.P.M |

Packing&Delivery

Packing:

Wooden box package is our standard & recommended packing, and the machine will be in sealed status. If export to european countries,the wooden material will be fumigated. For remoted countries, we suggest to use vacuum package.

Delivery time:

Basic Machine:30-35days

Jacquard Machine:45-50days

Cusomized Machine: 50days or More(depends on different situations)

Payment: TT or L/C is acceptable

Assembly workshop Cylinder workshop

CNC maching center Shipping goods

Certificate:

Application Area: Vest, T-shirt, Polo shirts, functional sportswear and underwear or seamless clothes(small size).

Applicable Yarn Materials: cotton, synthetic fiber, silk, artifical wool, mesh or elastic cloth.

Contact us:

![]() QuanZhou JingHe YuanWei Knitting Machinery Co.LTd

QuanZhou JingHe YuanWei Knitting Machinery Co.LTd

Add: Inside Honglei Stone Factory,Liaocuoqian,Luoyang Town, Hui'an County, Quanzhou City, Fujian Province, China

Phone/Whatsapp:+8613506078504

Website:https://www.jhknitmachinery.com/

Company Profile:

QuanZhou JingHe Circular Knitting Machinery Co.,LTD is the leading supplier of Circular Knitting machine, mainly produce Single Jersey Circular knitting machine, Double Jersey circular knitting machine,Jacquard Circular knitting machine.

Flexible customization and innovation, Strictly inspect each process of the product in the production process. Quality-oriented is the production philosophy of our factory, we strictly require that every process reach high standard. Therefore , a small screw must be layer of screened to ensure that each one must be bester

Advanced and intelligent production equipment and scientific management mode ensure that every detail from zero to the whole can be tracked in place. We have even established a complete service system for our customers, so that every customer is assured of our products and satisfied with our pre-sales and after-sales.