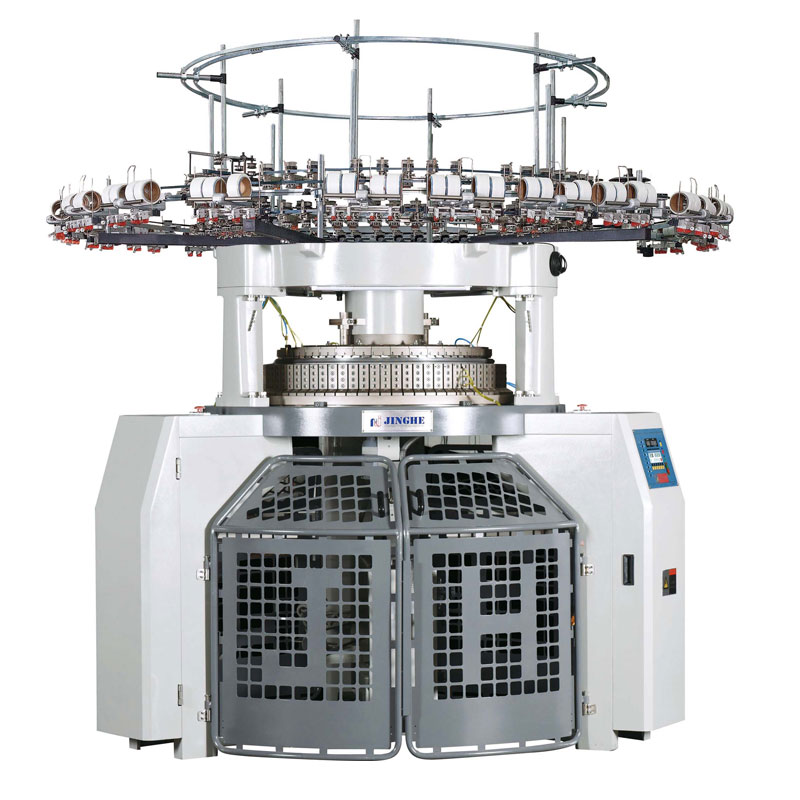

High Quality Professional Rib And Interlock Double Jersey Circular Knitting Machine

- Information

- Video

High Speed Circular Knitting Machine

Product description:

● 1.The cylinder seat is to prevent the bottom of the machine from spilling oil on the fabric. Both the large plate and the yarn feeder transmission gear box adopt oil-immersed design, which improves the stability, reduces noise and the influence of the fabric due to braking. The new large plate and large plate gear system can better support the long-term load impact of high tension and high load.

● 2.Powerful air dust fan and rotating nozzle can further enhance the dusting effect. Cam base can reduce batt accumulation. We have solved the problems that may occur under high-speed production for customers in advance。

● 3.The machine with 4 track production ordinary plain fabric and organization fabric, which are used in sports fabrics and casual clothing. Besides . from thick gauges to fine gauges; from small diameters to big diameters; from common fabric to bedding fabric ; from high-volume single yarn weaving to multi-spraying .and that can be equipped with open-width system and high-rolling frame . All of the above can be produced by this model to satisfy the various needs of different customers

The high-quality professional ribbed and ribbed double knitting circular machine is a knitting equipment used for manufacturing ribbed fabrics. Rib fabric is a common elastic fabric with obvious longitudinal elasticity and lateral shrinkage, commonly used in making elastic clothing such as bottoms, underwear, socks, etc.

This circular knitting machine has the following characteristics and functions:

High quality: The circular knitting machine is manufactured with high-quality materials and processes to ensure the stability and durability of the machine, which can operate stably for a long time and have a low failure rate.

Professional rib weaving: The circular knitting machine focuses on rib weaving and can easily produce various rib patterns, such as 1x1 rib, 2x2 rib, 3x1 rib, etc. The pattern and size of the rib pattern can be adjusted and changed as needed.

Double knitting technology: This circular knitting machine adopts double knitting technology, which means weaving on both sides simultaneously. This technology can make both sides of the fabric smoother and more uniform, improving the weaving effect and quality.

Accurate control system: The circular knitting machine is equipped with an accurate control system that can monitor and adjust parameters such as weaving tension, speed, and density in real-time, ensuring the consistency and stable quality of the fabric.

Diversified product applications: High quality professional ribbed and ribbed double knit circular machines are suitable for producing various ribbed fabric products, such as elastic pants, yoga suits, socks, underwear, etc.

For enterprises or individuals preparing to purchase or use ribbed and ribbed double knitting circular machines, it is recommended to understand the brand reputation, technical indicators, and after-sales service of the machine before choosing, and determine appropriate specifications and configurations based on specific product requirements. In addition, operators need to receive relevant training and guidance to fully utilize the functionality and performance of the machine

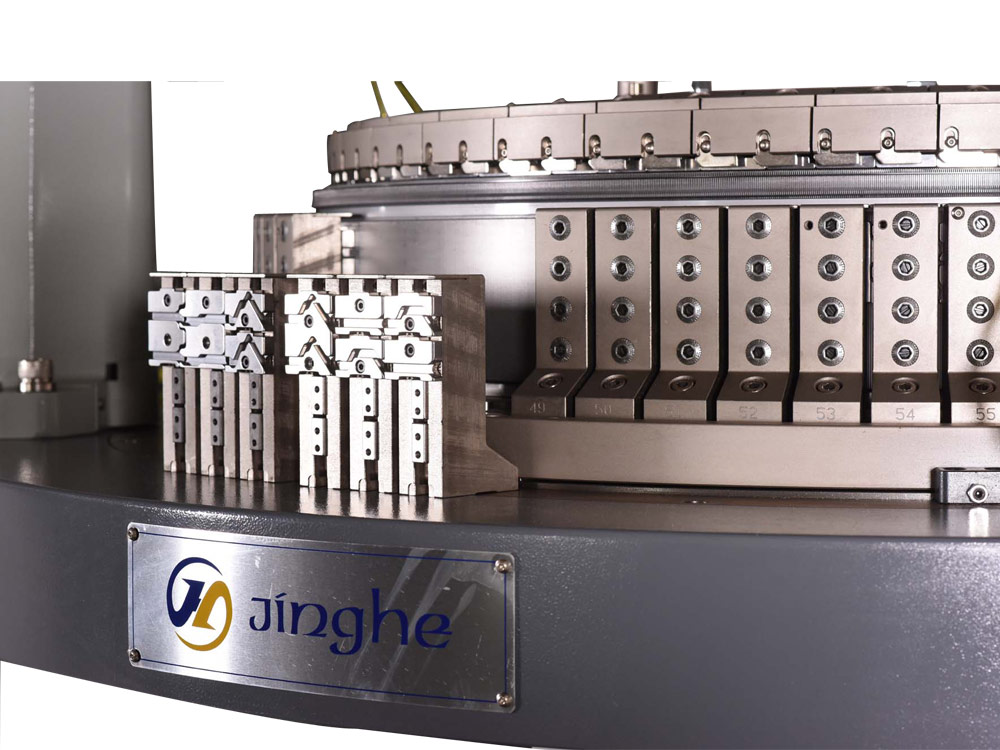

Circualr knitting machine Heart of Circular knitting machine

CNC machinging center Digital controlled lathe

Company Profile:

QuanZhou JingHe Circular Knitting Machinery Co.,LTD is the leading supplier of Circular Knitting machine, mainly produce Single Jersey Circular knitting machine, Double Jersey circular knitting machine,Jacquard Circular knitting machine.

Flexible customization and innovation, Strictly inspect each process of the product in the production process. Quality-oriented is the production philosophy of our factory, we strictly require that every process reach high standard. Therefore , a small screw must be layer of screened to ensure that each one must be bester

Advanced and intelligent production equipment and scientific management mode ensure that every detail from zero to the whole can be tracked in place. We have even established a complete service system for our customers, so that every customer is assured of our products and satisfied with our pre-sales and after-sales.

Technical Data

| Diameter | Feeders | Gauge | RPM |

| 25"-38"/2.1 | 52F-84F | 12G-40G | 18-40R.P.M |

| 25"-44"/2.4 | 60F-106F | 12G-40G | 18-40R.P.M |

| 30"-34"/3.2 | 96F-108F | 12G-32G | 18-40R.P.M |

| 25"-44"/2.8 | 70F-122F | 12G-32G | 18-40R.P.M |

Packing&Delivery

Packing:

Wooden box package is our standard & recommended packing, and the machine will be in sealed status. If export to european countries,the wooden material will be fumigated. For remoted countries, we suggest to use vacuum package.

Delivery time:

Basic Machine:30-35days

Jacquard Machine:45-50days

Cusomized Machine: 50days or More(depends on different situations)

Payment: TT or L/C is acceptable

Assembly workshop Cylinder workshop

CNC maching center Shipping goods

Certificate:

Application Area: Vest, T-shirt, Polo shirts, functional sportswear and underwear or seamless clothes(small size).

Applicable Yarn Materials: cotton, synthetic fiber, silk, artifical wool, mesh or elastic cloth.

Contact us:

![]() QuanZhou JingHe YuanWei Knitting Machinery Co.LTd

QuanZhou JingHe YuanWei Knitting Machinery Co.LTd

Add: Inside Honglei Stone Factory,Liaocuoqian,Luoyang Town, Hui'an County, Quanzhou City, Fujian Province, China

Phone/Whatsapp:+8613506078504

Website:https://www.jhknitmachinery.com/