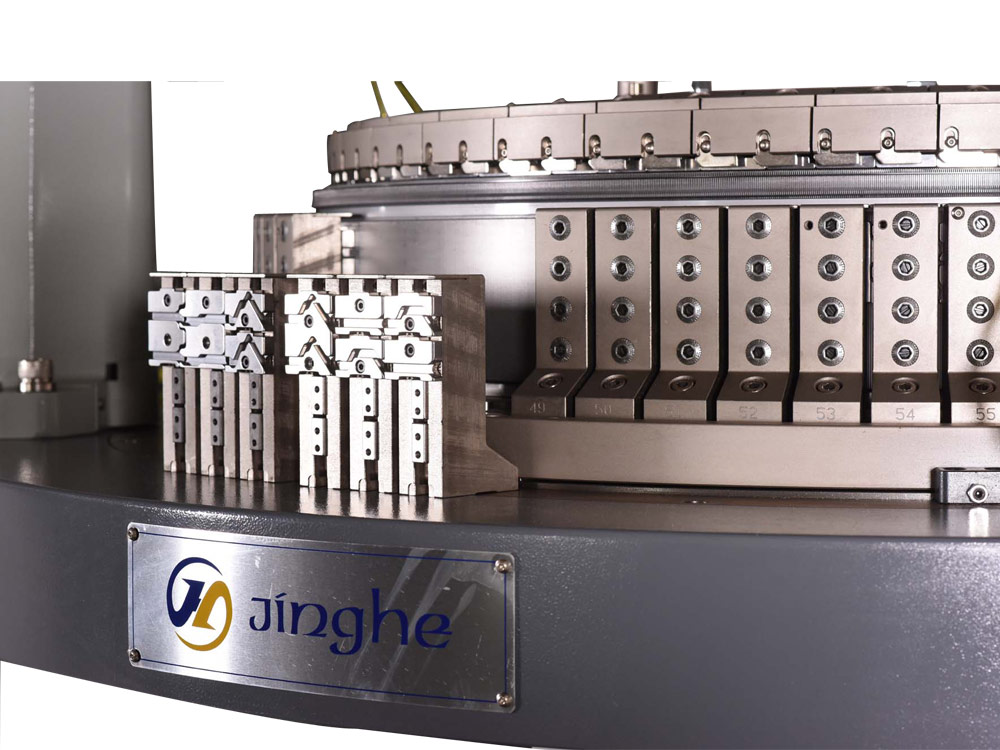

Single Circular Knitting Machine For Slik Cotton Fabrics

- Information

- Video

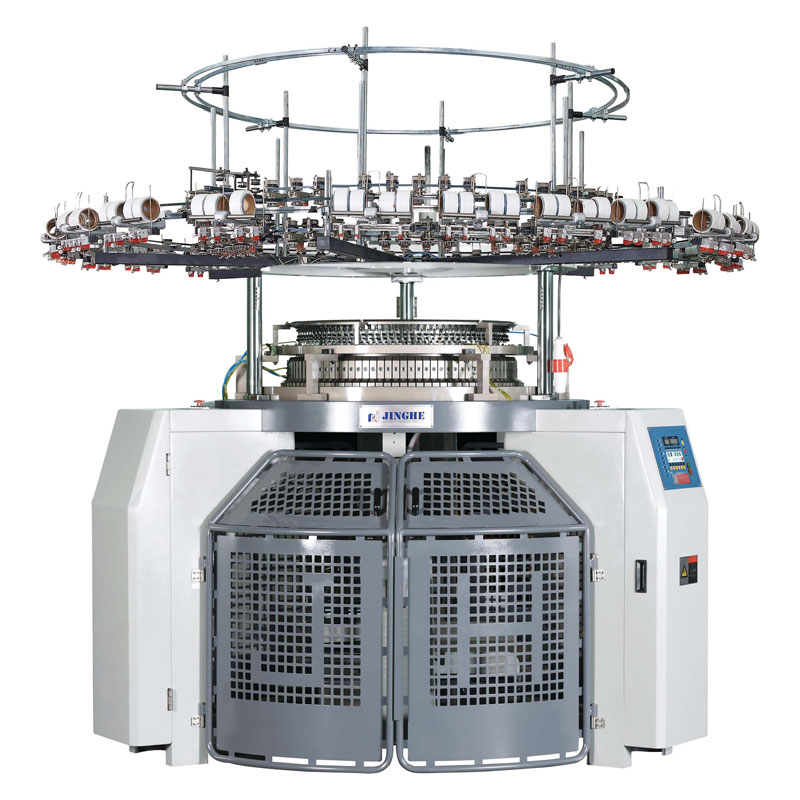

Single High Speed Circular Knitting Machine

Product description:

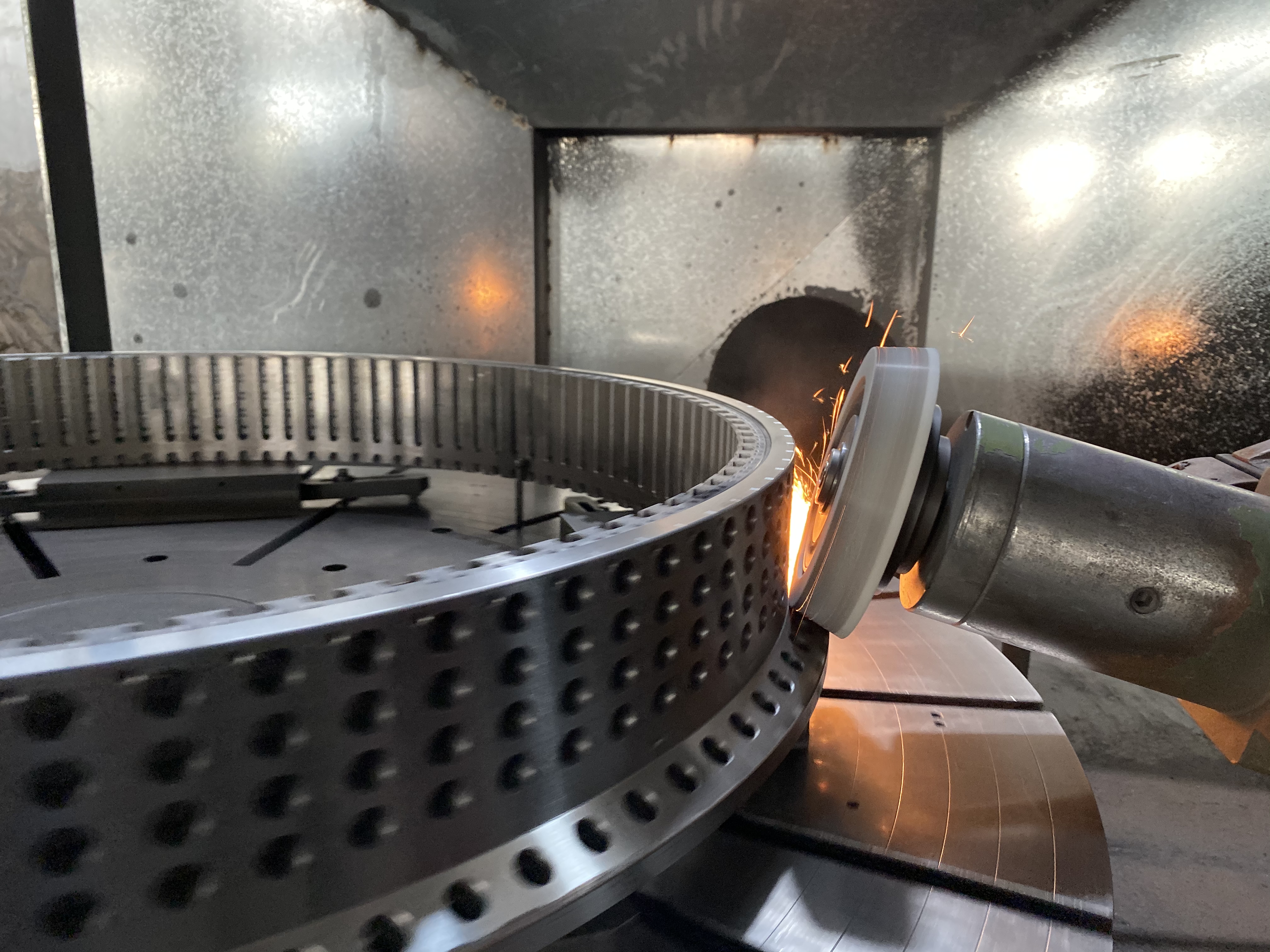

● 1.The cylinder seat is to prevent the bottom of the machine from spilling oil on the fabric. Both the large plate and the yarn feeder transmission gear box adopt oil-immersed design, which improves the stability, reduces noise and the influence of the fabric due to braking. The new large plate and large plate gear system can better support the long-term load impact of high tension and high load.

● 2.Powerful air dust fan and rotating nozzle can further enhance the dusting effect. Cam base can reduce batt accumulation. We have solved the problems that may occur under high-speed production for customers in advance。

● 3.The machine with 4 track production ordinary plain fabric and organization fabric, which are used in sports fabrics and casual clothing. Besides . from thick gauges to fine gauges; from small diameters to big diameters; from common fabric to bedding fabric ; from high-volume single yarn weaving to multi-spraying .and that can be equipped with open-width system and high-rolling frame . All of the above can be produced by this model to satisfy the various needs of different customers

Hello everyone, welcome to the forefront of technology exploration in this issue! Today we are going to talk about a promising new type of textile equipment - a single sided circular thin cotton fabric knitting machine. It has attracted widespread attention in the textile industry due to its unique design and efficient production methods.

Knitting machines, as one of the important production tools in the textile industry, have been continuously developed and improved. And this single sided circular thin cotton fabric knitting machine is an innovation and breakthrough on the basis of traditional knitting machines.

Firstly, let's take a look at the characteristics of this knitting machine. It adopts a circular design, making the production process more efficient and stable. Moreover, this machine can only be used for processing thin cotton fabric, which can greatly improve the production capacity and quality of the textile factory.

Secondly, we have to mention the core technology of this knitting machine - single sided process. Compared with traditional double-sided knitting machines, the single-sided process can effectively reduce scrap rates and improve product quality. This means that textile mills can achieve higher profits and competitiveness.

In addition, the single sided circular thin cotton fabric knitting machine also has a highly automated production process, reducing manual operations and improving work efficiency. This is undoubtedly a significant progress for the textile industry. Moreover, the use of electronic control technology also makes the device more intelligent and convenient.

On the contrary, in the current textile industry, market competition is becoming increasingly fierce, and the need to adapt to new technologies is becoming increasingly urgent. The emergence of single sided circular thin cotton fabric knitting machines has given textile manufacturers an opportunity to enhance their competitiveness. At the same time, the use of this equipment will also help improve the production environment of the textile industry and reduce its impact on the environment.

To remain invincible in this industry, companies must keep up with the pace of technology. I believe that with the promotion and application of single sided circular thin cotton fabric knitting machines, the textile industry will usher in a new transformation.

Technical Data

| Diameter | Feeders | Gauge | RPM |

| 10"-52"/3 | 30F-156F | 12G-40G | 18-40R.P.M |

| 10"-52"/3.2 | 32F-168F | 12G-40G | 18-40R.P.M |

| 10"-52"/4 | 40F-208F | 12G-32G | 18-40R.P.M |

| 10"-52"/6 | 60F-312F | 12G-32G | 18-40R.P.M |

Packing&Delivery

Packing:

Wooden box package is our standard & recommended packing, and the machine will be in sealed status. If export to european countries,the wooden material will be fumigated. For remoted countries, we suggest to use vacuum package.

Contact us:

![]() QuanZhou JingHe YuanWei Knitting Machinery Co.LTd

QuanZhou JingHe YuanWei Knitting Machinery Co.LTd

Add: Inside Honglei Stone Factory,Liaocuoqian,Luoyang Town, Hui'an County, Quanzhou City, Fujian Province, China

Phone/Whatsapp:+8613506078504

Website:https://www.jhknitmachinery.com/

Delivery time:

Basic Machine:30-35days

Jacquard Machine:45-50days

Cusomized Machine: 50days or More(depends on different situations)

Payment: TT or L/C is acceptable

Certificate:

Application Area: Vest, T-shirt, Polo shirts, functional sportswear and underwear or seamless clothes(small size).

Applicable Yarn Materials: cotton, synthetic fiber, silk, artifical wool, mesh or elastic cloth.