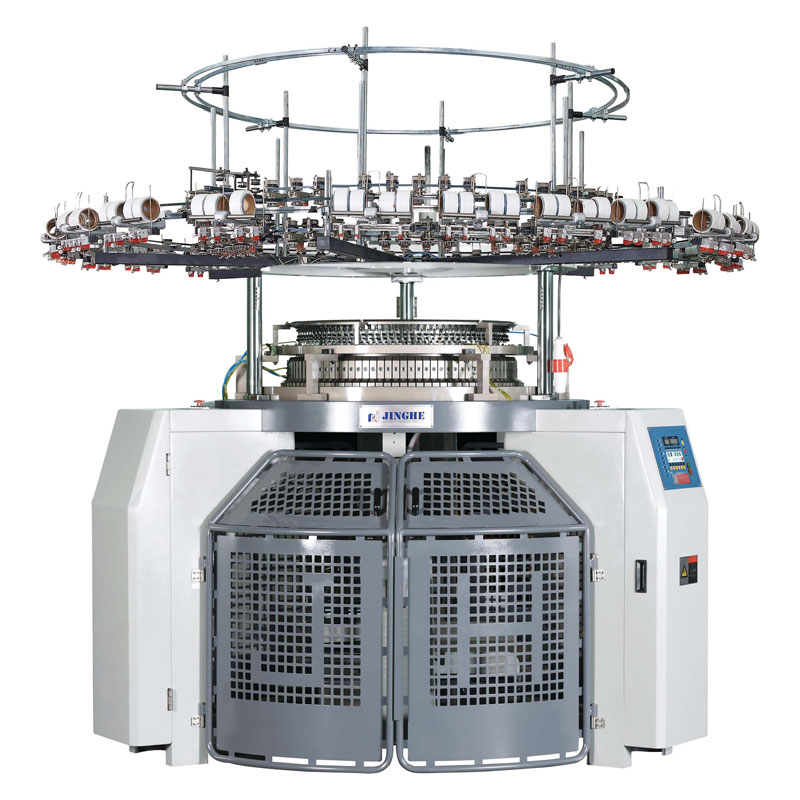

Two Side Loop Pile Circular Knitting Machine

- Information

- Video

Two Side Loop Pile Circular Knitting Machine

Product description:

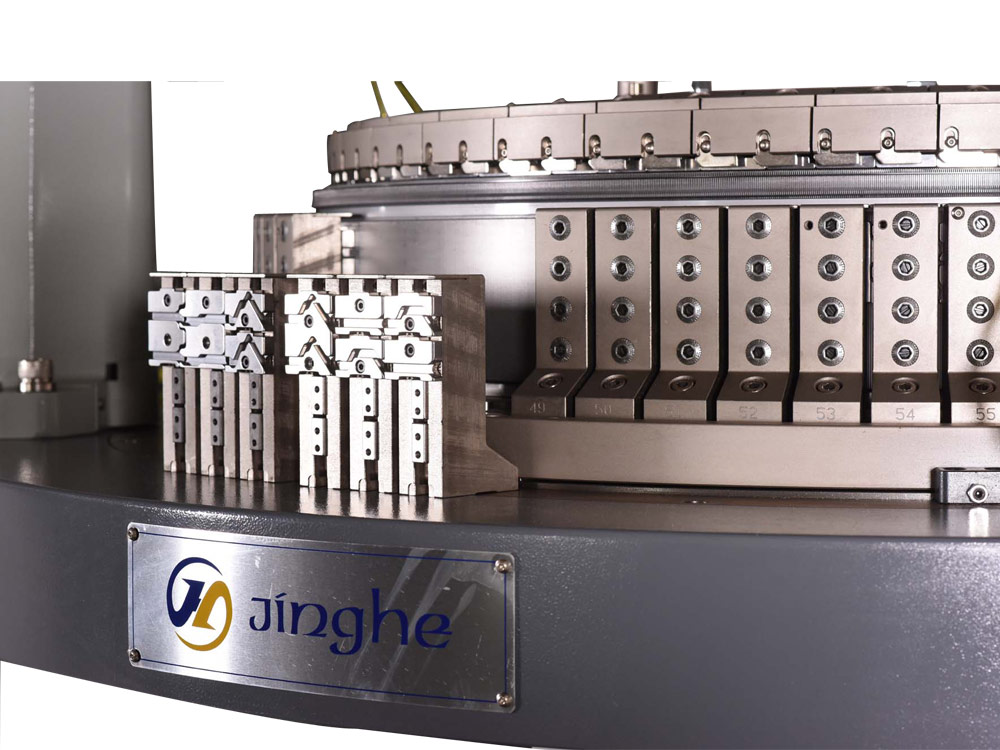

● 1.The cylinder seat is to prevent the bottom of the machine from spilling oil on the fabric. Both the large plate and the yarn feeder transmission gear box adopt oil-immersed design, which improves the stability, reduces noise and the influence of the fabric due to braking. The new large plate and large plate gear system can better support the long-term load impact of high tension and high load.

● 2.Powerful air dust fan and rotating nozzle can further enhance the dusting effect. Cam base can reduce batt accumulation. We have solved the problems that may occur under high-speed production for customers in advance。

● 3.The machine with 4 track production ordinary plain fabric and organization fabric, which are used in sports fabrics and casual clothing. Besides . from thick gauges to fine gauges; from small diameters to big diameters; from common fabric to bedding fabric ; from high-volume single yarn weaving to multi-spraying .and that can be equipped with open-width system and high-rolling frame . All of the above can be produced by this model to satisfy the various needs of different customers

The fashion industry has been constantly seeking innovation to meet the needs of different consumers for clothing. In recent years, as a new type of textile equipment, the double-sided loop knitting machine has attracted great attention and discussion in the fashion industry. Its unique design and application make clothing production more diverse and comfortable, and bring a new trend to the fashion industry.

So, what is a double-sided loop knitting machine? Simply put, it is a knitting machine that can simultaneously produce two different fabrics. By adjusting the stitch structure on both sides, it can simultaneously weave two different fabrics, inner and outer. Among them, the inner fabric is usually used to maintain warmth and comfort, while the outer fabric is used to showcase fashion and design.

The double-sided loop knitting machine has many unique advantages, let's take a look together.

Firstly, it can achieve the weaving of double-sided loop patterns. Traditional knitting machines can only achieve the weaving of a single fabric, while double-sided loop knitting circular machines can weave double-sided loop patterns with both longitudinal and three-dimensional effects through a special needle organization method. This feature makes clothing more outstanding in terms of touch and appearance, allowing people to feel unprecedented comfort and fashion.

Secondly, it has a high degree of diversity and plasticity. The double-sided loop knitting machine can design and produce different fabrics and patterns according to needs. Designers can adjust the color, texture, and thickness of fabrics at any time based on their creativity and fashion trends, providing more choices and flexibility.

In addition, it also has the ability to produce efficiently. The double-sided loop knitting circular machine can achieve high-speed weaving through an automated control system, greatly improving production efficiency. At the same time, it can also achieve one-time weaving of the entire fabric, reducing the steps of stitching, reducing waste of raw materials, and improving the overall yield.

The double-sided loop knitting machine has become a new favorite in the fashion industry. From sportswear to everyday clothing, from autumn and winter to spring and summer, we all benefit from its innovation and application. It not only brings people a more comfortable and fashionable wearing experience, but also brings more creativity and design possibilities to the fashion industry.

Of course, there are also some challenges in the development process of double-sided loop knitting circular machines. The first issue is the research and application of technology, which requires continuous innovation to improve the stability and efficiency of the equipment. Secondly, there are issues with the selection of raw materials and environmental protection. It is necessary to minimize the impact on the environment and choose sustainable materials.

Technical Data

| Diameter | Feeders | Gauge | RPM |

| 10"-52"/3 | 30F-156F | 12G-40G | 18-40R.P.M |

| 10"-52"/3.2 | 32F-168F | 12G-40G | 18-40R.P.M |

| 10"-52"/4 | 40F-208F | 12G-32G | 18-40R.P.M |

| 10"-52"/6 | 60F-312F | 12G-32G | 18-40R.P.M |

Packing&Delivery

Packing:

Wooden box package is our standard & recommended packing, and the machine will be in sealed status. If export to european countries,the wooden material will be fumigated. For remoted countries, we suggest to use vacuum package.

Delivery time:

Basic Machine:30-35days

Jacquard Machine:45-50days

Cusomized Machine: 50days or More(depends on different situations)

Payment: TT or L/C is acceptable

Certificate:

Application Area: Vest, T-shirt, Polo shirts, functional sportswear and underwear or seamless clothes(small size).

Applicable Yarn Materials: cotton, synthetic fiber, silk, artifical wool, mesh or elastic cloth.

FAQ:

Q : Where are your factory locates?

A : Our factory is located in QuanZhou city, FUJIAN province.

Q : Are all the main spare parts of the machine are produced by your factory?

A : Yes, all the main spare parts are produced by our factory with the most advanced processing.

Q : Will your machine be tested and adjusted before the machine delivery?

A : Yes, we will test and adjust the machine before delivery, also if the customer has special fabric demand, we can knit and test it in the machine before machine delivery

Q : Do you have after-sales service?

A : Yes, We have excellent after-sales service, can give a quick response, support in Chinese, English, Video

support is available.

Q :How long is the warranty period of the product?

A : We offer a warranty for about one year after customer received products.(Except for man-made damage)

Q : What are the main applications for the fabrics produced by your machines?

A : Fabrics knitted by our machines mainly can be used for Garments, Home textile ( like bedding sheet, mattress fabric, carpet), Sports fabric ( like Yoga fabric, diving fabric, sportswear ), Also for the jacquard machine, the pattern is easy to make by computer without limitation so the fabric can be widely used.

Contact us:

![]() QuanZhou JingHe YuanWei Knitting Machinery Co.LTd

QuanZhou JingHe YuanWei Knitting Machinery Co.LTd

Add: Inside Honglei Stone Factory,Liaocuoqian,Luoyang Town, Hui'an County, Quanzhou City, Fujian Province, China

Phone/Whatsapp:+8613506078504

Website:https://www.jhknitmachinery.com/